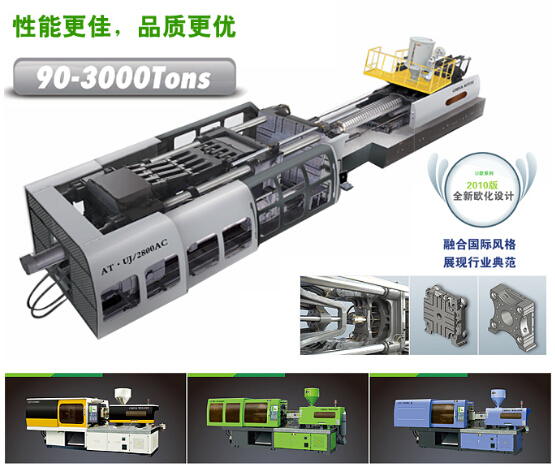

U precision injection molding machine

"Macao" too U section of precision injection molding machine fusion positioning design & technical parameters of the technical characteristics of the style of the design, highlighting the more Darong mold space, move mould and ejector stroke, structure design optimization

"Create a high performance closed-loop function design, with high-end technology to control & evolution, modular, personalized, precision, difference and practical quality function

The optimization design of the mechanical structure of the mechanical structure of the model and the rigid finite element model and the CAE dynamic simulation. The performance design and manufacture of plastics and injection parts, focusing on the precision, speed, and the consistency of the repetitive precision of the action.

"The electro-hydraulic control technology beyond the traditional design, the international brand of high quality components, to achieve high performance, high efficiency and energy saving

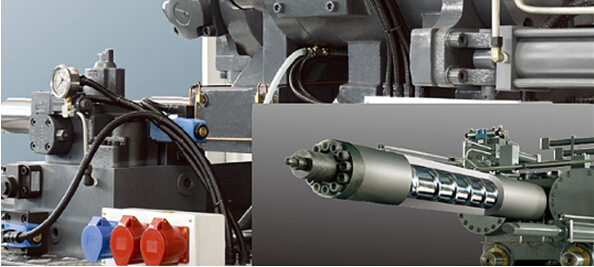

Design characteristics of locking device "Australia too" precision injection molding machine locking device combined with CAE simulation load optimization design, and the use of materials to enrich, high quality, show a strong high rigid and large capacity space of Taiwan model device.

breakthrough technology design, reliability, durability, quick and stable.

Bearing design, scientific and reasonable, material enrichment, rigid! |   |

Design characteristics of injection device

Plasticizing device "and" Macao "precision injection molding machine with customers long-term tracking and companies continue to experiment as the basis, to screw components using special high quality materials and processing, to structure and precision focus capture design and production, in order to achieve different results with the use of injection plastic high metering accuracy standard, each kind of product design has a, B, C three kinds of different diameter of nitride barrel / screw, quasi three choose a standard configuration. Such as hard chromium plating or dual metal, and other special types of products can be processed according to the requirements of customers.

"Plastic & injection machine is very sensitive part of the core, therefore, according to the types of product design were used multicomponent closed-loop function of man-machine interface in real time control system to achieve high precision density, high response of injection molding.

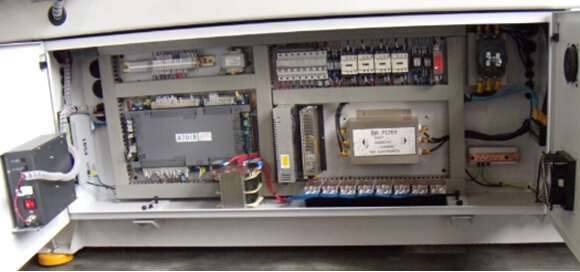

electrical system

"World famous brand and high quality electrical components: to ensure the stability and reliability of the

Regular distribution and precision assembly work: the accident risk is reduced to a minimum, it is easier to maintain

"A powerful extension of the function: support for a variety of options, such as the robot interface, etc.

Mold closing system